- Home

- Products

products

Gang tool lathe

Turret lathe

Turn-mill compound machine tool

Dual spindle turn-mill compound

Precision surface grinder

ModelP120

P160

P200

Processing range

MoreMaximum spin diameter on the saddleΦ320mm

Maximum turning diameterΦ300mm

Standard turning diameterΦ120mm

Rotation diameter on carriageΦ126mm

Maximum turning length300mm

Chuck size5'

Bar capacityΦ36mm

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ300mm

Standard turning diameterΦ150mm

Rotation diameter on carriageΦ126mm

Maximum turning length340mm

Chuck size6'

Bar capacityΦ46mm

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ300mm

Standard turning diameterΦ150mm

Rotation diameter on carriageΦ126mm

Maximum turning length320mm

Chuck size8'

Bar capacityΦ52mm

ProductsModelC160

C200

C250

C300

SpecificationC200-300

C200-500

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ320mm

Standard turning diameterΦ200mm

Rotation diameter on carriageΦ300mm

Maximum turning length300mm

Chuck size8'

Bar capacityΦ52mm

Processing range

MoreMaximum spin diameter on the saddleΦ560mm

Maximum turning diameterΦ400mm

Standard turning diameterΦ200mm

Rotation diameter on carriageΦ300mm

Maximum turning length488mm

Chuck size8'

Bar capacityΦ52mm

SpecificationC250-500

C250-1000

Processing range

MoreMaximum spin diameter on the saddleΦ560mm

Maximum turning diameterΦ400mm

Standard turning diameterΦ250mm

Rotation diameter on carriageΦ300mm

Maximum turning length488mm

Chuck size5'

Bar capacityΦ52mm

Processing range

MoreMaximum spin diameter on the saddleΦ580mm

Maximum turning diameterΦ500mm

Standard turning diameterΦ300mm

Rotation diameter on carriageΦ1000mm

Maximum turning length500mm

Chuck size10'

Bar capacityΦ72mm

SpecificationC300-1000

C300-1500

C300-2000

Processing range

MoreMaximum spin diameter on the saddleΦ730mm

Maximum turning diameterΦ620mm

Standard turning diameterΦ300mm

Rotation diameter on carriageΦ440mm

Maximum turning length1000mm

Chuck size12'

Bar capacityΦ75mm

Processing range

MoreMaximum spin diameter on the saddleΦ730mm

Maximum turning diameterΦ620mm

Standard turning diameterΦ300mm

Rotation diameter on carriageΦ440mm

Maximum turning length1500mm

Chuck size12'

Bar capacityΦ75mm

Processing range

MoreMaximum spin diameter on the saddleΦ730mm

Maximum turning diameterΦ640mm

Standard turning diameterΦ300mm

Rotation diameter on carriageΦ440mm

Maximum turning length2240mm

Chuck size12'

Bar capacityΦ75mm

SpecificationModelP160Y

P160MY

C160M

C160MY

C200M

C200MY

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ320mm

Standard turning diameterΦ200mm

Rotation diameter on carriageΦ300mm

Maximum turning length300mm

Chuck size6'

Bar capacityΦ46mm

Processing range

MoreMaximum spin diameter on the saddleΦ480mm

Maximum turning diameterΦ200mm

Standard turning diameterΦ150mm

Rotation diameter on carriageΦ250mm

Maximum turning length300mm

Chuck size6'

Bar capacityΦ46mm

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ320mm

Standard turning diameterΦ200mm

Rotation diameter on carriageΦ300mm

Maximum turning length300mm

Chuck size6'

Bar capacityΦ52mm

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ225mm

Standard turning diameterΦ150mm

Rotation diameter on carriageΦ300mm

Maximum turning length240mm

Chuck size6'

Bar capacityΦ42mm

Processing range

MoreMaximum spin diameter on the saddleΦ400mm

Maximum turning diameterΦ320mm

Standard turning diameterΦ200mm

Rotation diameter on carriageΦ300mm

Maximum turning length300mm

Chuck size8'

Bar capacityΦ52mm

Processing range

MoreMaximum spin diameter on the saddleΦ560mm

Maximum turning diameterΦ330mm

Standard turning diameterΦ200mm

Rotation diameter on carriageΦ300mm

Maximum turning length450mm

Chuck size8'

Bar capacityΦ52mm

ModelC200MYS

CX200

Processing range

MoreSpindle through apertureΦ66mm

Spindle bearing diameterNN3020+100BAR+NN3018

Hydraulic cylinder bore8'

Spindle noseA 2-6

Spindle motor power22kW

Spindle transmission modeDirect drive

Spindle transmission ratio1:1

Spindle speed4300rpm

Spindle rated output speed2320rpm(220V)

Processing range

MoreSpindle through apertureΦ66mm

Spindle bearing diameterNN3020+100BAR+NN3018

Hydraulic cylinder bore8'

Spindle noseA 2-6

Spindle motor power22kW

Spindle transmission modeDirect drive

Spindle transmission ratio1:1

Spindle speed4300rpm

Spindle rated output speed2320rpm(220V)

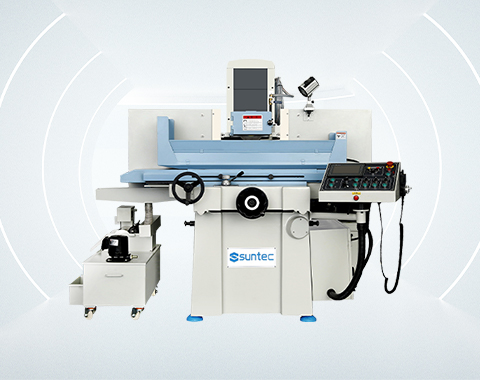

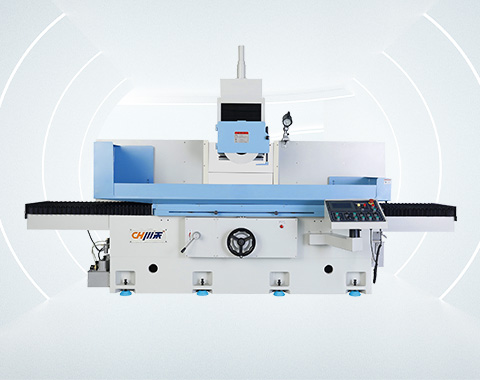

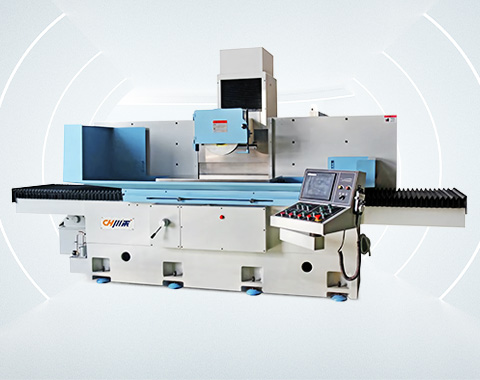

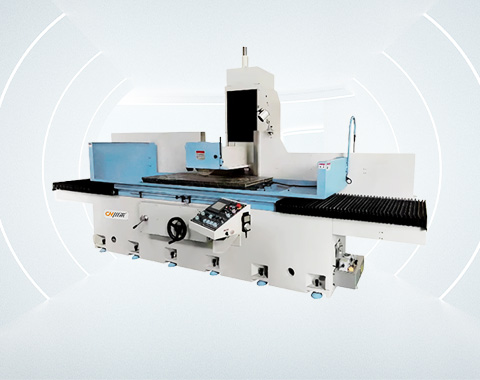

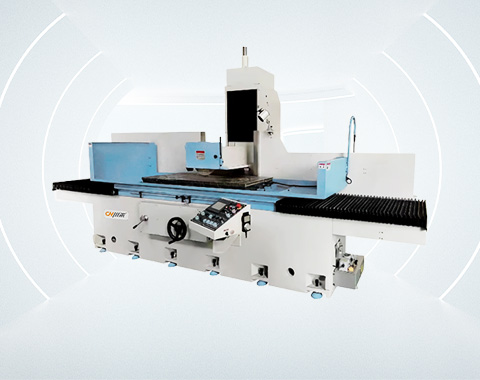

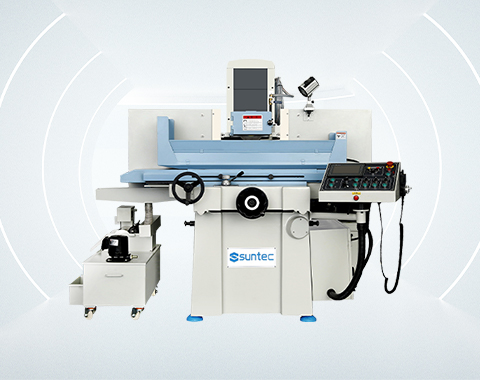

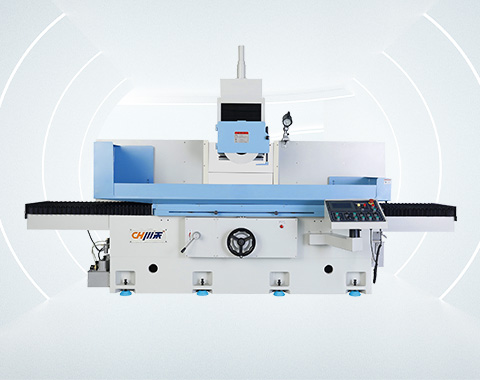

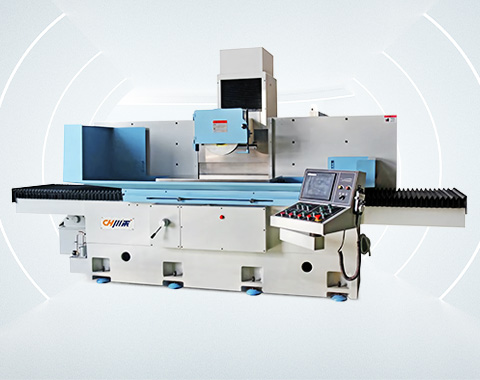

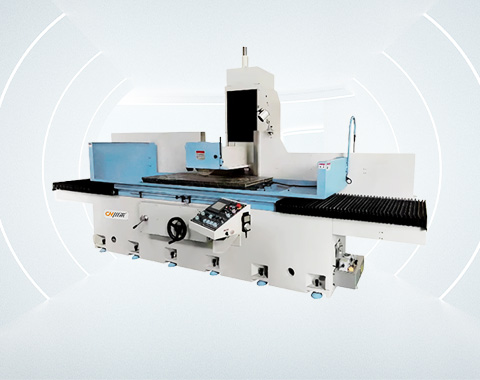

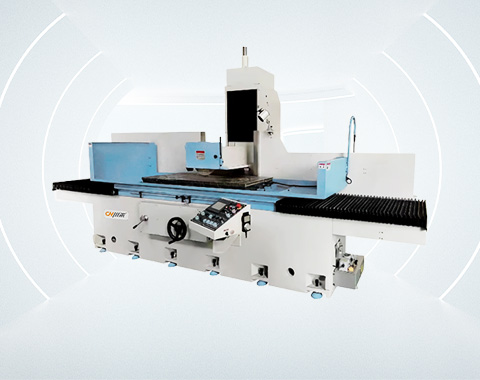

ProductsSeriesSaddle surface grinder

Movable column surface grinder

CNC surface grinder

ModelG818A

G818S

G2550A

G2550S

G306K

G306S

G408K

G408S

Processing range

MoreTable working area460X200mm

Maximum left and right movement540mm

Maximum forward and backward movement250mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench150kg

Workbench T-slot14mm×1N

Workbench speed5~25m/min

Processing range

MoreTable working area460X200mm

Maximum left and right movement540mm

Maximum forward and backward movement240mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench150kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area500X250mm

Maximum left and right movement560mm

Maximum forward and backward movement275mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench250kg

Workbench T-slot14mm×1N

Workbench speed5~25m/min

Processing range

MoreTable working area500X250mm

Maximum left and right movement560mm

Maximum forward and backward movement275mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench250kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area600×300mm

Maximum left and right movement680mm

Maximum forward and backward movement340mm

Maximum distance from work surface to spindle center570mm

Maximum weight of the workbench420kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area600×300mm

Maximum left and right movement680mm

Maximum forward and backward movement340mm

Maximum distance from work surface to spindle center570mm

Maximum weight of the workbench420kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area800×400mm

Maximum left and right movement880mm

Maximum forward and backward movement450mm

Maximum distance from work surface to spindle center580mm

Maximum weight of the workbench700kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area800×400mm

Maximum left and right movement880mm

Maximum forward and backward movement450mm

Maximum distance from work surface to spindle center580mm

Maximum weight of the workbench700kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

ModelG5010S

G5012S

G6015S

G6030S

G7020S

Processing range

MoreTable working area1000X500mm

Maximum left and right movement1140mm

Maximum forward and backward movement540mm

Maximum distance from work surface to spindle center600mm

Maximum weight of the workbench800kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area1200X500mm

Maximum left and right movement1340mm

Maximum forward and backward movement540mm

Maximum distance from work surface to spindle center600mm

Maximum weight of the workbench800kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area1500×600mm

Maximum left and right movement1600mm

Maximum forward and backward movement660mm

Maximum distance from work surface to spindle center700mm

Maximum weight of the workbench800kg

Workbench T-slot16mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area3000×600mm

Maximum left and right movement3250mm

Maximum forward and backward movement660mm

Maximum distance from work surface to spindle center700mm

Maximum weight of the workbench1500kg

Workbench T-slot16mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area2000×700mm

Maximum left and right movement2230mm

Maximum forward and backward movement760mm

Maximum distance from work surface to spindle center700mm

Maximum weight of the workbench1500kg

Workbench T-slot16mm×3N

Workbench speed2~25m/min

ModelG818A

G818S

G2550A

G2550S

G306K

G306S

G408K

G408S

G5010S

G5012S

G6015S

G6030S

G7020S

Processing range

MoreTable working area460X200mm

Maximum left and right movement540mm

Maximum forward and backward movement250mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench150kg

Workbench T-slot14mm×1N

Workbench speed5~25m/min

Processing range

MoreTable working area460X200mm

Maximum left and right movement540mm

Maximum forward and backward movement240mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench150kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area500X250mm

Maximum left and right movement560mm

Maximum forward and backward movement275mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench250kg

Workbench T-slot14mm×1N

Workbench speed5~25m/min

Processing range

MoreTable working area500X250mm

Maximum left and right movement560mm

Maximum forward and backward movement275mm

Maximum distance from work surface to spindle center475mm

Maximum weight of the workbench250kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area600×300mm

Maximum left and right movement680mm

Maximum forward and backward movement340mm

Maximum distance from work surface to spindle center570mm

Maximum weight of the workbench420kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area600×300mm

Maximum left and right movement680mm

Maximum forward and backward movement340mm

Maximum distance from work surface to spindle center570mm

Maximum weight of the workbench420kg

Workbench T-slot14mm×1N

Workbench speed2~25m/min

Processing range

MoreTable working area800×400mm

Maximum left and right movement880mm

Maximum forward and backward movement450mm

Maximum distance from work surface to spindle center580mm

Maximum weight of the workbench700kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area800×400mm

Maximum left and right movement880mm

Maximum forward and backward movement450mm

Maximum distance from work surface to spindle center580mm

Maximum weight of the workbench700kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area1000X500mm

Maximum left and right movement1140mm

Maximum forward and backward movement540mm

Maximum distance from work surface to spindle center600mm

Maximum weight of the workbench800kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area1200X500mm

Maximum left and right movement1340mm

Maximum forward and backward movement540mm

Maximum distance from work surface to spindle center600mm

Maximum weight of the workbench800kg

Workbench T-slot14mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area1500×600mm

Maximum left and right movement1600mm

Maximum forward and backward movement660mm

Maximum distance from work surface to spindle center700mm

Maximum weight of the workbench800kg

Workbench T-slot16mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area3000×600mm

Maximum left and right movement3250mm

Maximum forward and backward movement660mm

Maximum distance from work surface to spindle center700mm

Maximum weight of the workbench1500kg

Workbench T-slot16mm×3N

Workbench speed2~25m/min

Processing range

MoreTable working area2000×700mm

Maximum left and right movement2230mm

Maximum forward and backward movement760mm

Maximum distance from work surface to spindle center700mm

Maximum weight of the workbench1500kg

Workbench T-slot16mm×3N

Workbench speed2~25m/min

- Gallery

- Service Support

- News

- About us

首页

首页 经营范围

经营范围 电话咨询

电话咨询 留言

留言